close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

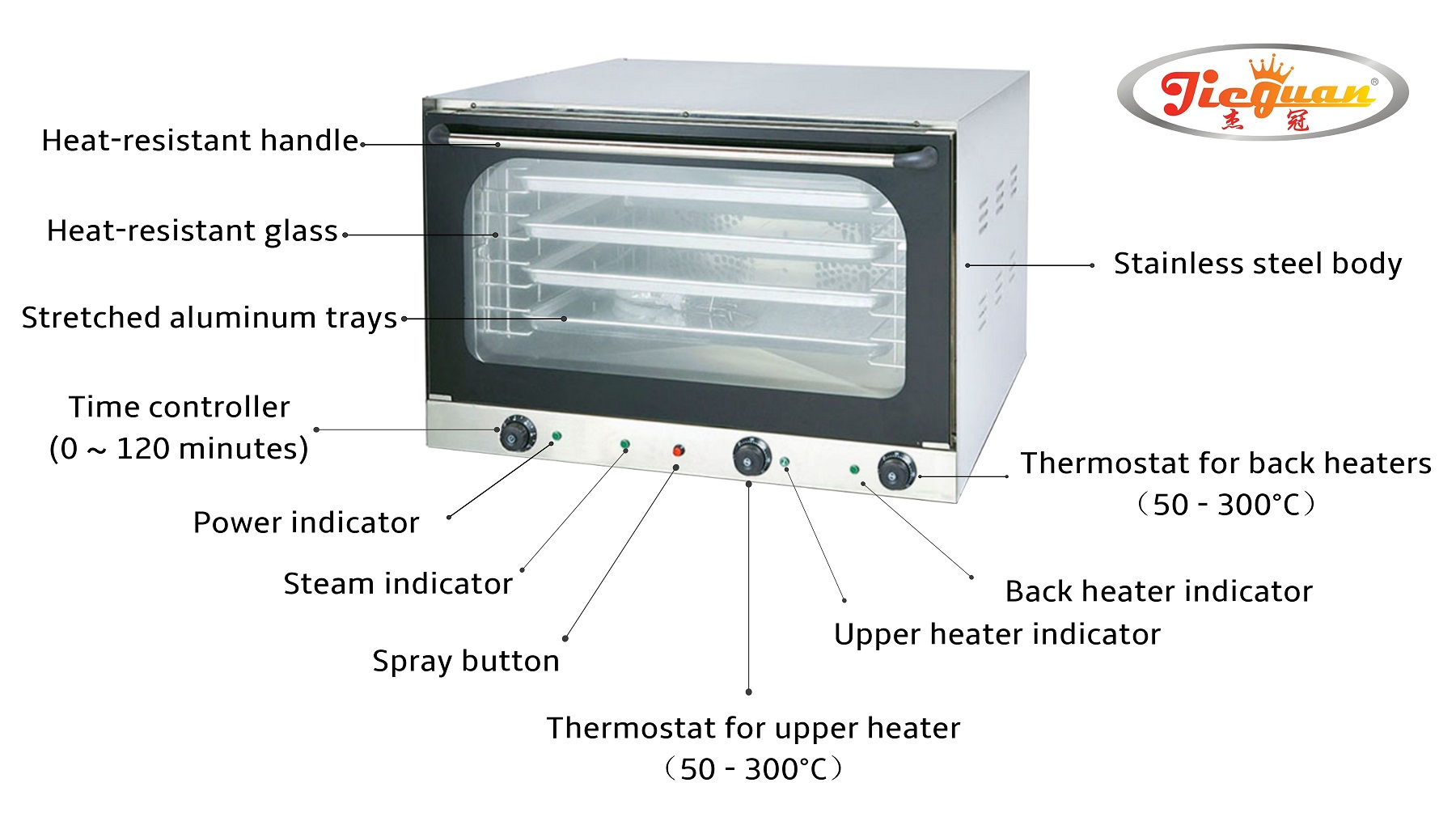

EB-8A

JIEGUAN

A convection oven uses a fan to circulate hot air around food. This improves heat transfer and reduces uneven baking. It helps you bake faster and more consistently than still-air ovens.

Best for you when you need:

Even browning across multiple trays

Faster batch baking in limited space

A counter-top format for back-of-house lines

Higher consistency: Forced air reduces hot spots and tray-to-tray variance.

Better throughput: Faster heat recovery supports busy service windows.

Moisture control: The spray function supports selected bakery applications.

Easy training: Clear controls reduce operator errors.

OEM-ready supply: You can build your private label product line.

You get a practical chamber size for small bakeries and restaurants. It fits many standard tray workflows.

Air circulation supports uniform color and texture. You can reduce rotation time during peak hours.

A controlled spray can support surface finish in some recipes. It may also reduce crust drying in early stages.

Stainless housing supports daily use and easy cleaning. Insulation helps reduce heat loss.

You can use this oven for:

Bread rolls and pastries

Roasted meats and vegetables

Frozen-to-ready snacks

Small-batch catering production

Common buyer profiles:

Importers and distributors

Restaurant groups and chains

Bakery suppliers and equipment wholesalers

Central kitchens and catering operators

Final specs depend on your target market. Share your voltage, tray size, and control preference.

| Item | Reference Value | Custom Options |

|---|---|---|

| Chamber volume | 86 L | Other capacities available |

| Type | Counter-top electric convection | Stand option |

| Heating | Electric elements + fan | Multi-fan designs |

| Spray | Built-in spray function | Manual or auto timing |

| Control | Thermostat / timer (varies) | Digital / programmable |

| Shelves | Multi-level rails | Rail spacing options |

| Material | Stainless steel body | Grade and thickness options |

| Voltage | 220–240V common | 110V / 50–60Hz options |

Your country and power standard

Tray size and maximum load per batch

Target temperature range and timer needs

Preferred packaging and spare parts kit

A convection oven is a fan-assisted baking system. It circulates hot air to improve uniformity.

Many kitchens plan 10–30% faster bake times versus still-air, recipe dependent.

Forced air can reduce tray rotation frequency in multi-level baking.

For frozen snacks, consistent airflow helps reduce center underbake risk.

Plan 2–6 trays per bake cycle for small back-of-house lines.

Keep one spare fan motor per 20–50 units in service fleets.

Stock heating elements and thermostats to shorten downtime.

Start with your peak-hour demand. Then match chamber volume to batch size.

If staff turnover is high, simple controls reduce mistakes. If you need repeatability, consider programmable settings.

Spray can support certain bakery finishes. You should match spray use to your recipes.

Jieguan supports B2B customization for global wholesalers and importers.

OEM options

Logo badge, panel printing, and carton artwork

Multi-language manuals and safety labels

Plug, voltage, and wiring adaptation

Accessory bundles for your sales channel

ODM options

Chamber and rail layout adjustments

Control logic, presets, and spray timing

Housing updates to match your product line

You should align equipment selection with local safety and food operations. Request inspection photos and functional testing records before shipping.

For food-service temperature and safety guidance, refer to the U.S. FDA Food Code resource: https://www.fda.gov/food/fda-food-code/food-code-2022

Export packaging choices

Foam-protected carton for standard routes

Optional wooden crate for long-distance shipping

Palletizing for container loading efficiency

Shipping support

Documentation coordination for customs

Spare parts kit planning for distributors

Inspection support prior to dispatch

Send your target market, voltage, and tray requirements.

Confirm specification and OEM items.

Review quotation and production schedule.

Approve artwork for private label orders.

Arrange inspection and shipping terms.

You get faster pricing when you share:

Order quantity and destination port

Incoterm preference

Any compliance requirements in your market

It is used for baking and roasting with circulating hot air. It improves uniformity and speed.

Often yes. Many recipes finish faster. You should test your standard products.

It can add moisture at controlled moments. This may improve crust and surface finish.

Airflow helps reduce uneven baking. Rotation may still help with dense loads.

Yes. You can customize logo, labels, cartons, and manuals.

Often yes. Share your voltage, frequency, and plug type for confirmation.

Clean the chamber, check seals, and inspect fan operation. Stock common spare parts.

Provide tray size, target capacity, voltage, and your destination market rules.

A convection oven uses a fan to circulate hot air around food. This improves heat transfer and reduces uneven baking. It helps you bake faster and more consistently than still-air ovens.

Best for you when you need:

Even browning across multiple trays

Faster batch baking in limited space

A counter-top format for back-of-house lines

Higher consistency: Forced air reduces hot spots and tray-to-tray variance.

Better throughput: Faster heat recovery supports busy service windows.

Moisture control: The spray function supports selected bakery applications.

Easy training: Clear controls reduce operator errors.

OEM-ready supply: You can build your private label product line.

You get a practical chamber size for small bakeries and restaurants. It fits many standard tray workflows.

Air circulation supports uniform color and texture. You can reduce rotation time during peak hours.

A controlled spray can support surface finish in some recipes. It may also reduce crust drying in early stages.

Stainless housing supports daily use and easy cleaning. Insulation helps reduce heat loss.

You can use this oven for:

Bread rolls and pastries

Roasted meats and vegetables

Frozen-to-ready snacks

Small-batch catering production

Common buyer profiles:

Importers and distributors

Restaurant groups and chains

Bakery suppliers and equipment wholesalers

Central kitchens and catering operators

Final specs depend on your target market. Share your voltage, tray size, and control preference.

| Item | Reference Value | Custom Options |

|---|---|---|

| Chamber volume | 86 L | Other capacities available |

| Type | Counter-top electric convection | Stand option |

| Heating | Electric elements + fan | Multi-fan designs |

| Spray | Built-in spray function | Manual or auto timing |

| Control | Thermostat / timer (varies) | Digital / programmable |

| Shelves | Multi-level rails | Rail spacing options |

| Material | Stainless steel body | Grade and thickness options |

| Voltage | 220–240V common | 110V / 50–60Hz options |

Your country and power standard

Tray size and maximum load per batch

Target temperature range and timer needs

Preferred packaging and spare parts kit

A convection oven is a fan-assisted baking system. It circulates hot air to improve uniformity.

Many kitchens plan 10–30% faster bake times versus still-air, recipe dependent.

Forced air can reduce tray rotation frequency in multi-level baking.

For frozen snacks, consistent airflow helps reduce center underbake risk.

Plan 2–6 trays per bake cycle for small back-of-house lines.

Keep one spare fan motor per 20–50 units in service fleets.

Stock heating elements and thermostats to shorten downtime.

Start with your peak-hour demand. Then match chamber volume to batch size.

If staff turnover is high, simple controls reduce mistakes. If you need repeatability, consider programmable settings.

Spray can support certain bakery finishes. You should match spray use to your recipes.

Jieguan supports B2B customization for global wholesalers and importers.

OEM options

Logo badge, panel printing, and carton artwork

Multi-language manuals and safety labels

Plug, voltage, and wiring adaptation

Accessory bundles for your sales channel

ODM options

Chamber and rail layout adjustments

Control logic, presets, and spray timing

Housing updates to match your product line

You should align equipment selection with local safety and food operations. Request inspection photos and functional testing records before shipping.

For food-service temperature and safety guidance, refer to the U.S. FDA Food Code resource: https://www.fda.gov/food/fda-food-code/food-code-2022

Export packaging choices

Foam-protected carton for standard routes

Optional wooden crate for long-distance shipping

Palletizing for container loading efficiency

Shipping support

Documentation coordination for customs

Spare parts kit planning for distributors

Inspection support prior to dispatch

Send your target market, voltage, and tray requirements.

Confirm specification and OEM items.

Review quotation and production schedule.

Approve artwork for private label orders.

Arrange inspection and shipping terms.

You get faster pricing when you share:

Order quantity and destination port

Incoterm preference

Any compliance requirements in your market

It is used for baking and roasting with circulating hot air. It improves uniformity and speed.

Often yes. Many recipes finish faster. You should test your standard products.

It can add moisture at controlled moments. This may improve crust and surface finish.

Airflow helps reduce uneven baking. Rotation may still help with dense loads.

Yes. You can customize logo, labels, cartons, and manuals.

Often yes. Share your voltage, frequency, and plug type for confirmation.

Clean the chamber, check seals, and inspect fan operation. Stock common spare parts.

Provide tray size, target capacity, voltage, and your destination market rules.